INTELLIGENT TOOL HANDLING SOLUTIONS - MEET OUR PRODUCTS!

Stock Terminal

The smallest member of the family is the Stock Terminal, which is an intelligent stock managing software, controllable on touchscreen. Choosing the appropriate product picture from the pictures of products in the warehouse, the product admission is captured, so the warehouse keeper is relieved of the administrative burden. Limits and restrictions can be set per worker, product or even product family.

- intelligent stock managing software, controllable on touchscreen

- captured product admission

- card or barcode identification system

- simplification of administrative burdens

- limits and restrictions per worker, product or even product family

- unique queries, data export, developed reporting system

StockMat ECO

The most economic member of the family is the StockMat ECO vending machine. Its design makes 6-tray storage available for smaller products (in particular, gloves). The machine (which is suited for basic equipment market needs, with advantageous historical costs) is characterised by a mechanical door, welded sheet structures and a loading door which can be opened with a key.

|

|

| TECHNICAL DATA | |

| Width: Depth: Height: Voltage: Power consumption: Control circuit: Unladen weight: Interior storage trays: Size of tray: Number of engines stackable on one tray: Load capacity per tray: Total load capacity: | 1046 mm 926 mm 1830 mm 230V/ 50 Hz 6 A 12 / 24 VDC 270 kg max. 6 pcs 742×595 mm max. 10 pcs of simple engines max. 5 pcs of twin engines 60 kg 360 kg |

StockMat

The most versatile member of the family is the StockMat vending machine, which is able to store various products, from personal protection equipment to manufacturing tools, with up to 7-tray design. The precise trackability of the tool register is ensured by an uninterruptible power supply in order to avoid inconveniences originating from power surges or power outage. Security is also ensured by the automatic horizontal door above the loading slot. The user-friendly software a offers highly-developed reporting system next to the unique queries and data exporting.

|

|

| TECHNICAL DATA | |

| Width: Depth: Height: Voltage: Power consumption: Control circuit: Unladen weight: Interior storage trays: Size of tray: Number of engines stackable on one tray: Load capacity per tray: Total load capacity: | 1160 mm 1000 mm 1800 mm 230V/ 50 Hz 6 A 24 VDC 280 kg max. 7 pcs 742×595 mm max. 10 pcs of simple engines max. 5 pcs of twin engines 60 kg 420 kg |

StockMat Safe

The safest member of the family is the StockMAT Safe vending machine, which is able to portion products with high gas concentration (eg. flammable and explosive sprays) in a controlled and safe way. In case of gas leakage, it gives 2 types of signals.

- safe dispensing of spray bottles containing fire and explosion hazardous gases

- compliant with ex-proof standard requirements

- gravitational air circulation

- warning pictograms

- 2 types of signals: alarm light and sound

- upon gas concentration of 20% the red light gives alarm; calling for inspection of the machine and ventilation.

- upon gas concentration of 40% the dispenser switches off; authorised professional may open the service door to remove faulty and/or hazardous product, following ventilation the interior of the machine can be freed from gases

TECHNICAL DATA

| Width: Depth: Height: Voltage: Power consumption: Control circuit: Unladen weight: Interior storage trays: Size of tray: Number of engines stackable on one tray: Load capacity per tray: Total load capacity: | 1160 mm 1000 mm 1800 mm 230V/ 50 Hz 6 A 24 VDC 280 kg max. 7 pcs 742×595 mm max. 10 pcs of simple engines max. 5 pcs of twin engines 60 kg 420 kg |

StockMat Lapka

The most complex member of the family is StockMat Lapka, an automat with combined functions. Above the spiralled and sectioned portioning, it makes the servicing of the tiny sheets with jars possible. There are 768 pieces of available jars. The used sheets can be taken back.

|

|

| TECHNICAL DATA | |

| Width: Depth: Height: Voltage: Power consumption: Control circuit: Unladen weight: Interior storage trays: Size of tray: Load capacity per tray: | 1160 mm 1000 mm 1800 mm 230V/ 50 Hz 6 A 24 VDC 2 pcs with spiral, 4 pcs with conveyor belt 4 pcs 742×595 mm 60 kg |

DispoMat SHG

...

- dispensing products stored in pieces or in bulk in a controlled way

- checking height and weight

- checking function traced back to weight

- storage boxes of usable dimensions of 400 mm x 600 mm x 250 mm that can be replaced by any storage box available in the market

- automatic door and safety light curtain

- touch screen and user-friendly platform

- painted with individual colours (ESD painting)

...

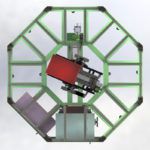

DispoMat Sectioned

The most intelligent member of the family is the new generation paternoster system. The slatted door structure with horizontal moving makes the opening per sections possible. Perforated spacings are designed on the trays, so different entitlements can be defined within one tray. Equipped with a security light curtain for hand detection. Equipped with a user friendly, touchscreen interface.

|

|

| TECHNICAL DATA | |

Width: | 3300 mm |

DispoMat Standard

The most practical member of the family is the paternoster system which is able to offer storage possibility for bigger tools, templates and parts with a load capacity of 200kg/tray. The intactness of the products to be stored is ensured by a security gate. The system is able to start gradually, smoothly and to stop the shelves precisely in delivery position. Equipped with a user friendly, touchscreen interface.

|

|

| TECHNICAL DATA | |

Width: | 3300 mm |